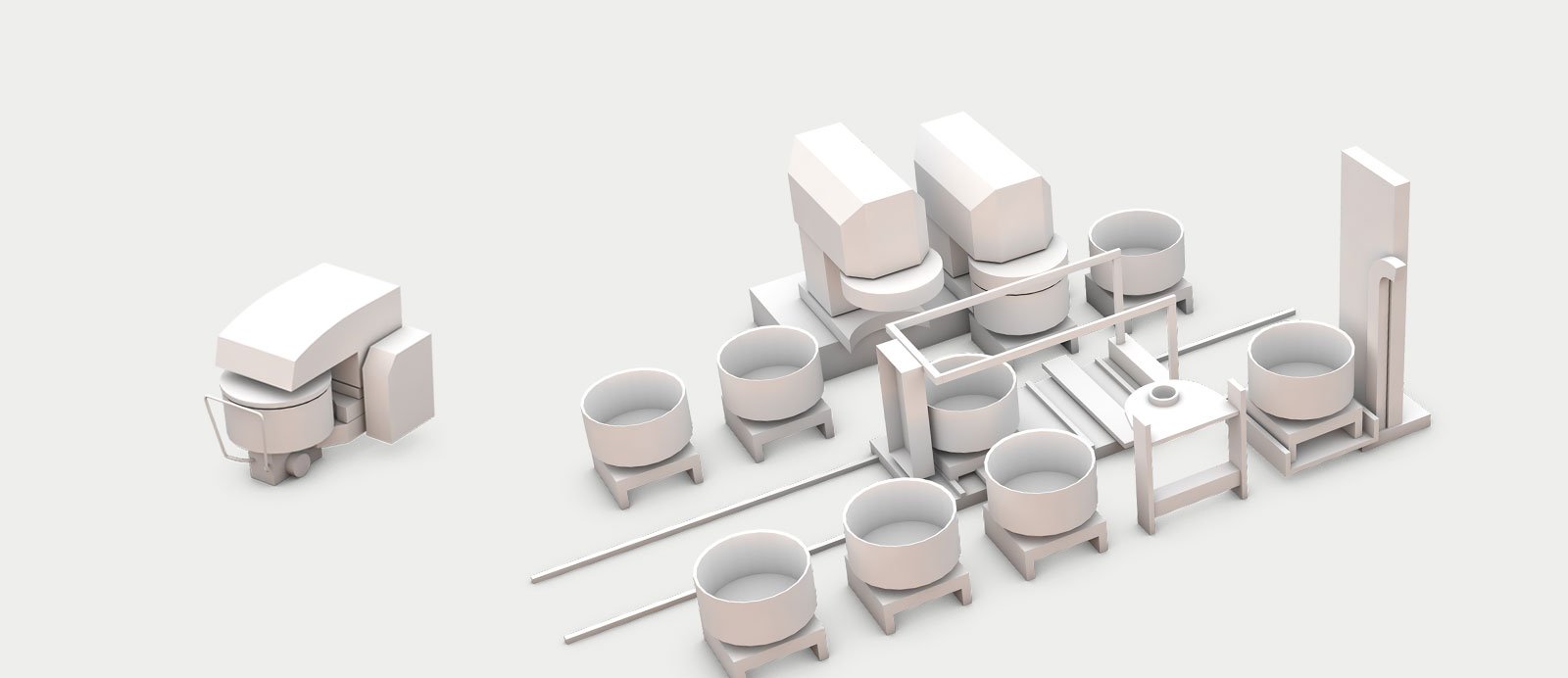

Stand-alone mixers and fully automatic

mixing systems ensure high dough quality

and perfectly mixed doughs.

- Spiral mixer

- Helix mixer

- Mixing systems

Automatic mixing systems

What makes the

quality of an optimal dough?

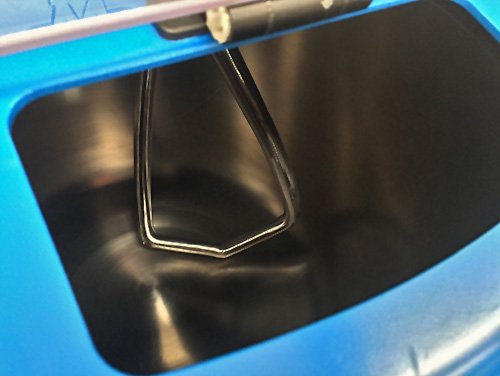

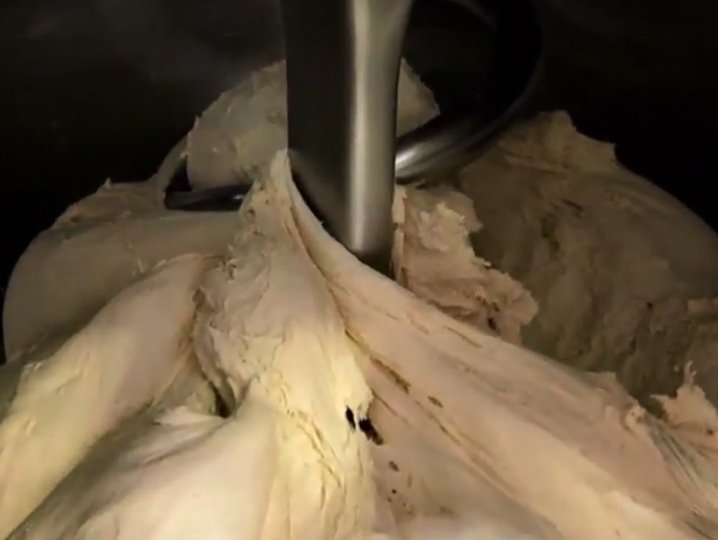

Good raw materials are essential for good doughs as the quality of water and flour significantly influences the dough quality. In addition to the raw materials, optimal mixing ensures the best product quality. Each dough has different requirements, soft doughs require a lot of tension and volume, rye doughs have to be mixed gently. Mixing tools matched to the type of dough increase the quality of the dough.

High dough quality through

sophisticated technology

When it comes to dough quality, there is nobody out there who knows the business better than us. Our systems are second to none, both in traditional dough processing relying on stand-alone universal mixers or single batch equipment, and in industrial dough processing with fully automated mixing systems precisely customized to specific production conditions. Our 3-zone mixing principle always ensures optimally mixed doughs.

Fully automatic mixing systems

WP Kemper mixing systems are customized to the specific product and process requirements of industrial bakeries to ensure optimal integration and networking of all parts in the overall process.

3-zone mixing principle

All WP Kemper spiral mixers (mixing systems and stand-alone mixers) are equipped with our proprietary 3-zone mixing system. This patented process adds more oxygen to the dough, producing soft, easy to process doughs in reproducible quality.

Service

The use of monitoring systems to control all relevant component temperatures and central lubrications for moving components offer maximum reliability and extend the service life of our mixers and mixing systems. Sometimes it happens and a damage occurs. With our Serviceline 24/7 we are always available to initiate and implement the necessary actions as quickly as possible.

Highest dough quality

Because doughs made with our mixers are aerated and easy to process.

Reliable

Through resilient materials and high manufacturing accuracy.

Versatile

The right solution for every dough requirement.

Low personnel deployment

The intelligent control of the mixing systems leaves room for the efficient use of the personnel.

MIXING

Our sales representative will gladly answer your questions about our mixing solutions.

![Mixing system POWER ROLL SYSTEM [Translate to Englisch:]](/fileadmin/_processed_/a/8/csm_WP-Kemper_Knetsystem-POWER-ROLL-SYSTEM_t_99083112f3.jpg)

![Mixing system TITAN LINEAR SYSTEM [Translate to Englisch:]](/fileadmin/_processed_/d/c/csm_WP-Kemper_Knetsystem-TITAN-LINEAR-SYSTEM-t_2fe374d393.jpg)

![Mixer UC PRO [Translate to Englisch:]](/fileadmin/_processed_/5/8/csm_WP-Kemper_Wendelkneter-UC-PRO-t_24b9e85e15.png)

![Mixer SP [Translate to Englisch:]](/fileadmin/_processed_/b/e/csm_WP-Kemper_Spiralkneter-SP-t_e374ec2bd1.png)

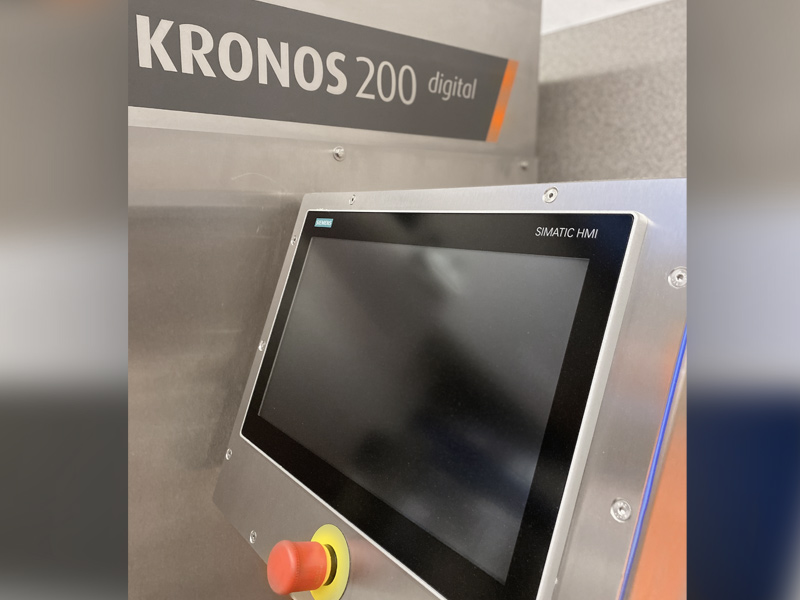

![Mixer KRONOS digital [Translate to Englisch:]](/fileadmin/_processed_/1/5/csm_WP-Kemper_Spiralkneter-KRONOS-digital-t_e9c2c13d59.png)

![Mixing system AUTOMATIC TITAN [Translate to Englisch:]](/fileadmin/_processed_/6/7/csm_WP-Kemper_Knetsystem-AUTOMATIC-TITAN-t_e01d60d6ac.jpg)

![Mixer POWER MIXER [Translate to Englisch:]](/fileadmin/_processed_/d/0/csm_WP-Kemper_Bodenentleerungskneter-POWER_MIXER-t_d3cefdba54.png)