Optimal solutions for

the industrial production

of buns and rolls

- 1 g weight accuracy

- 60 strokes / minute

- 36,000 pieces / hour

Industrial Roll Production

What makes the quality of rolls?

Rolls are eaten all over the world every day. Kaiser rolls for breakfast or lunch, Hamburger and Hot Dog buns as a quick meal and chocolate rolls or milk buns as a sweet snack in between. There is an almost infinite variety of types, shapes or patterns of rolls. So, what makes the quality of a good bun?

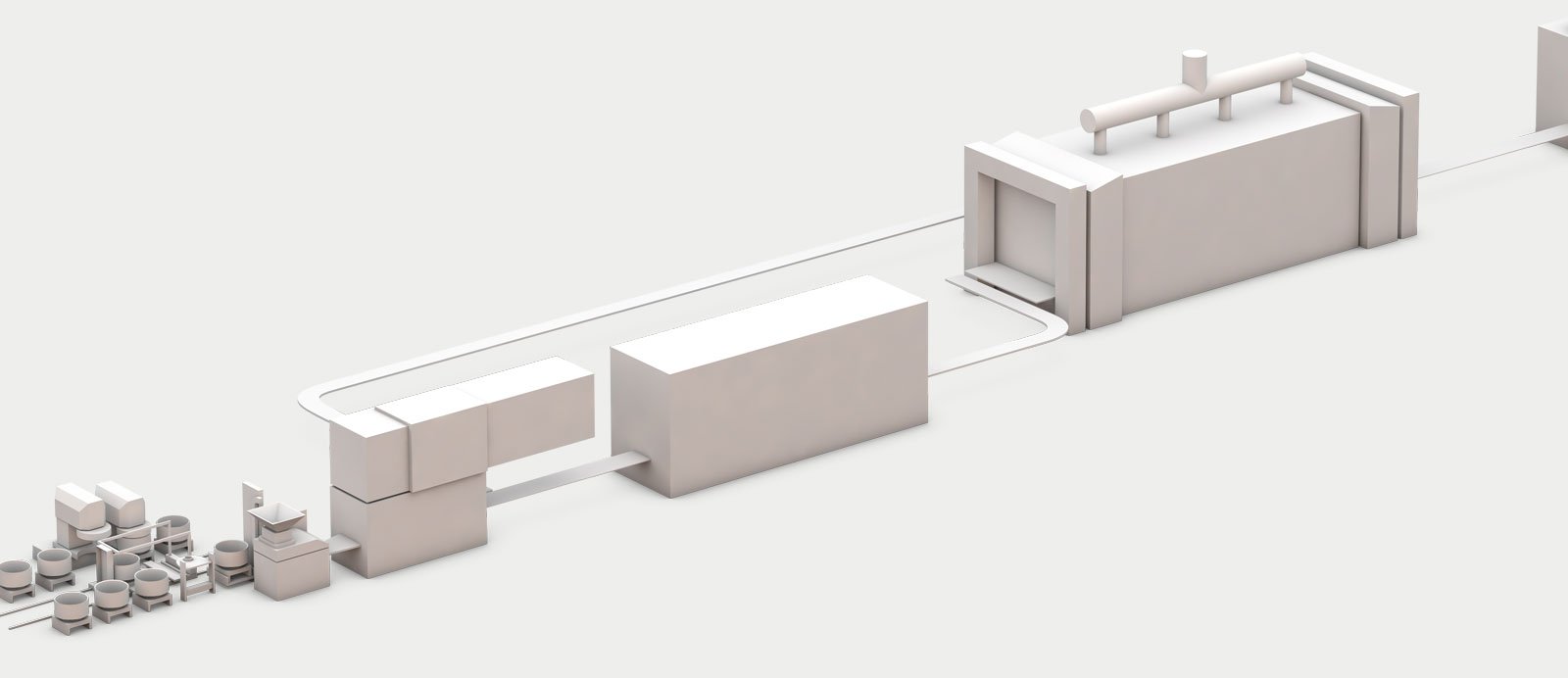

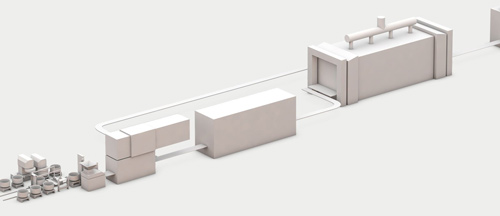

Turnkey process solutions

for the industrial bun production

Complete roll production processes consist of coordinated components that enable efficient and continuous production of industrial baked goods. The production systems developed and installed by us are fully customized turn key solutions covering all processes from dough production through to the finished product.

Soft & Sweet

Up to 36,000 pcs./h

Process example for hamburger

buns, briochette, hot dog buns

and pain au lait

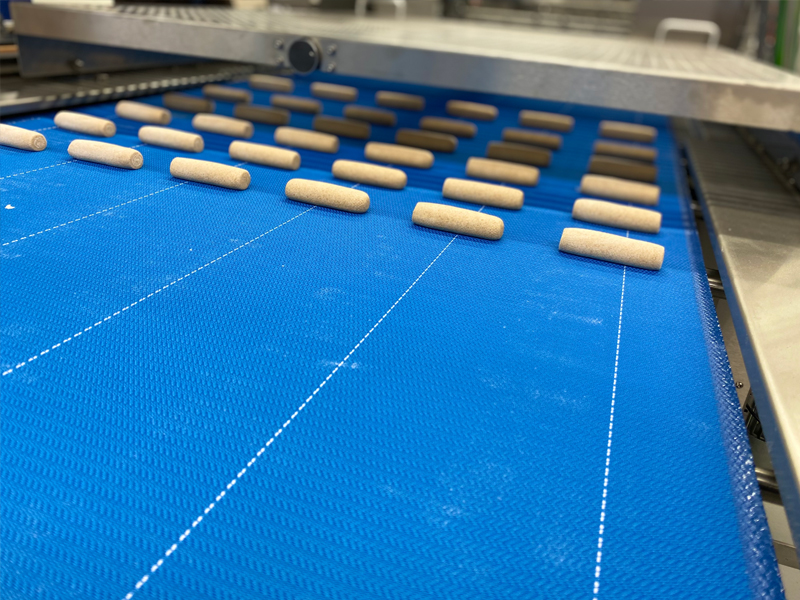

FLEXI

Up to 36,000 pcs./h

Process example for round,

longmoulded, stamped, flat

pressed, folded and curled rolls

Coordinated components

We find the right solution for our customer´s needs and ensure that all modules are optimally networked. Our customers have only one point of contact when it comes to rolls.

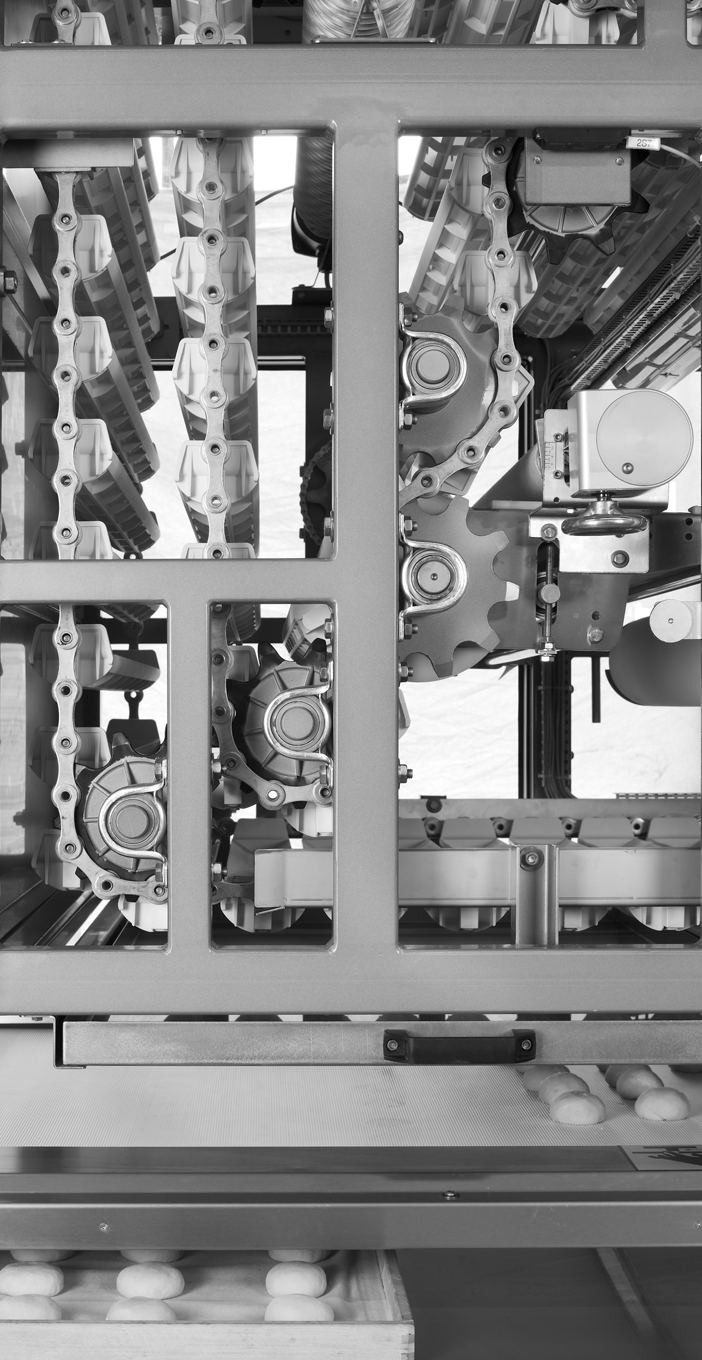

POWER ROLL SYSTEM

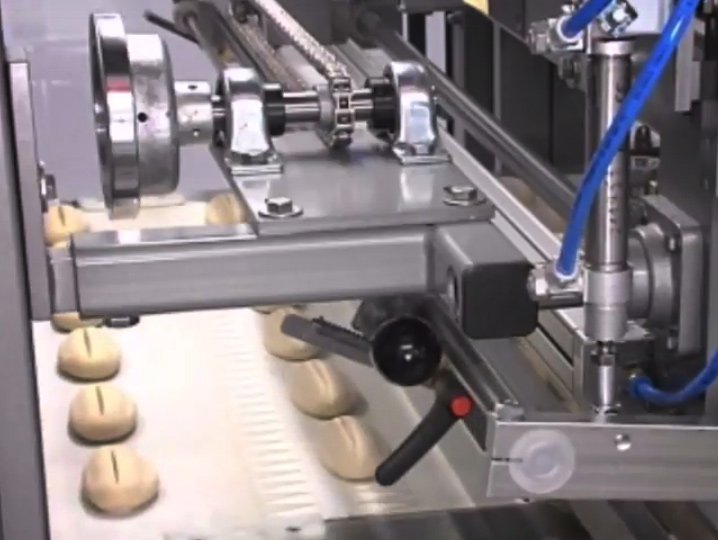

SOFT STAR CTi

EVOLUTION

Scope of supply and service

We do not just deliver the machines, we also assume the complete project planning. We take account of process requirements, desired product characteristics and specific site situations, and we collaborate closely with our customers to design the optimum solution for their needs.

Technology

Our turn-key solutions are equipped with the latest technologies and high-quality components. Nearly all elements in our systems are WP Kemper products. We collaborate closely with our customers to find the right partners for any additional modules.

Service

Our service includes the delivery, installation and set-up of the roll line, as well as the service needed. Through training of the machine operators and house technicians and regular maintenance, we want to make it possible to plan machine downtimes. But sometimes it comes to an unplanned machine downtime. With spare parts on stock and our Serviceline 24/7, we are available for you around the clock.

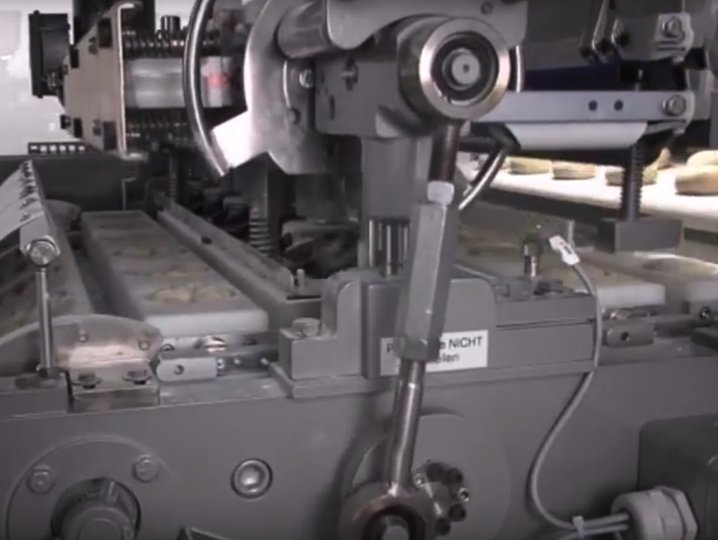

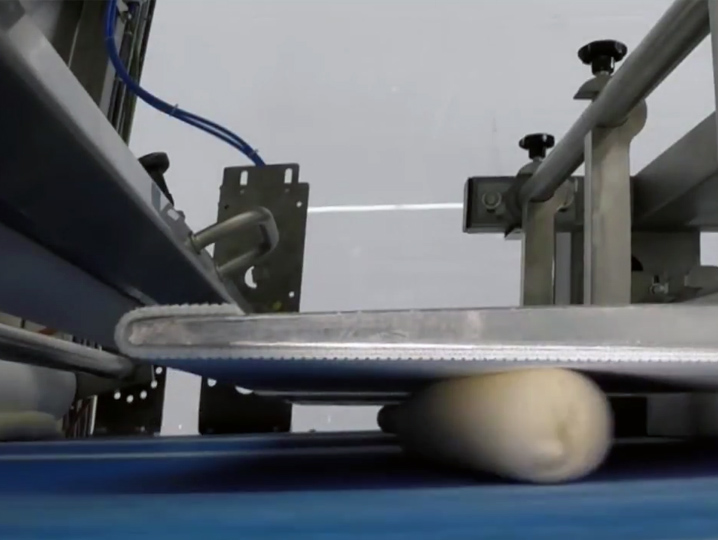

Highest precision

And exact processing with the EVOLUTION roll line.

99% weight accuracy

With the head machines of the SOFT STAR series.

High product quality

By gentle dough production and processing.

Fully automatic, coordinated process steps

we kemper it.

WP ROLL provides optimum production solutions for the industrial production of rolls all the way from dough processing through to freezing. We look after all engineering aspects, we design and deliver customized turn-key solutions. As mechanical engineers, we know what it takes to get a project right.

Our sales representative will gladly answer your questions about our roll process solutions.