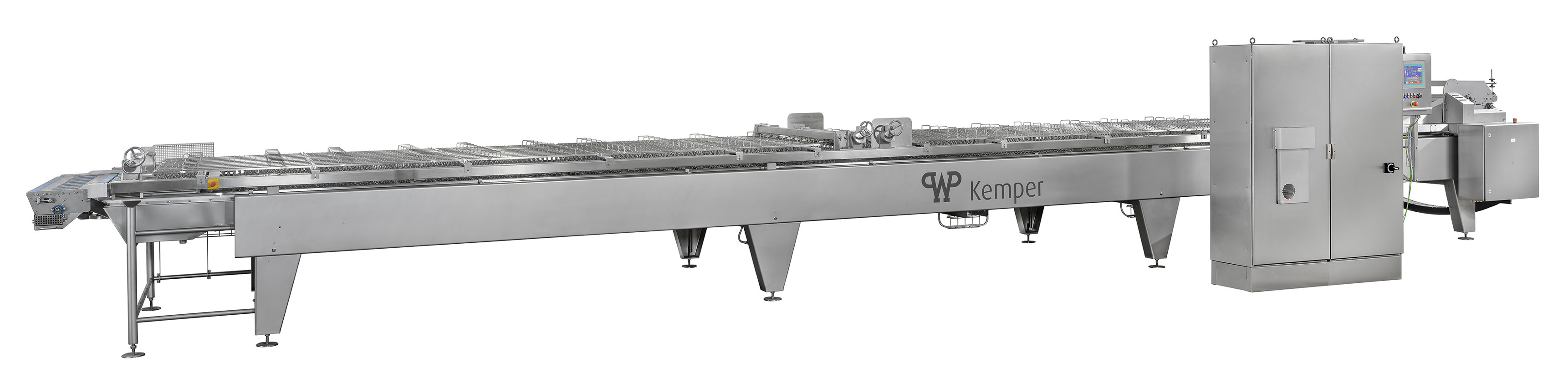

Fryer

LARGO

We have developed the LARGO fryer to make it a powerful and reliable partner for your deep-fried pastry production. The sensitive Berliners and donuts are treated particularly gentle and the flexibility of the LARGO makes it possible to process different product sizes and product types. The LARGO fryer always fits your individual product and production requirements and is particularly energy-efficient and very easy to clean.

Machine variants

LARGO with basket transport

Number of pieces: Up to 50,400 pcs/h

(at 100 seconds baking time)

Working width: 1,100 mm ; 1,540 mm

Baskets: 43 - 83

Product turning via turning station

LARGO with bar transport

Number of pieces: Up to 50,400 pcs/h

(at 100 seconds baking time)

Working width: 1,100 mm ; 1,540 mm

Baskets: 43 - 83

Product turning via turning wheel

LARGO with heating rods

Number of pieces: Up to 50,400 pcs/h

(at 100 seconds baking time)

Working width: 1,100 mm ; 1,540 mm

Baskets: 43 - 83

Electrical heating system

LARGO with frying oil heat exchanger

Number of pieces: Up to 50,400 pcs/h

(at 100 seconds baking time)

Working width: 1,100 mm ; 1,540 mm

Baskets: 43 - 83

Heating with thermal oil

Advantages and benefits of the fryer LARGO

For best quality donuts and ball donuts

High processing quality

from product infeed to decorating.

Capacity

pieces / hour

Up to 9,800 pieces/hour

at 100 seconds baking time

pieces / hour

Up to 50,400 pieces/hour

at 100 seconds baking time

Equipment and options of the fryer LARGO

For the optimal use of your deployed ressources

We develop and build all our production lines and machines completely in our own company. The decisive performance features of our lines are their high functional reliability, their excellent proftability and the consistently high quality of all products they make.

Product infeed

- Height-adjustable infeed conveyor and therefore adaptable to product shape and size

- Gentle tipping or swimming

Transport baskets and turning stations

- Continuous transport baskets for small, medium and large products

- Transport bars with pre-defined bar distance and turning ramp

- The dough pieces are fixed in the running direction and are gently guided

- Continuous, gentle transport and smooth oil level

- Up to 3 turning stations freely selectable and switchable

Insulation

- Double wall insulation in the pan floor and wall

- Hardly any heat radiation, thus significantly reducing the risk of injury

- High energy saving

Options

- Thermal oil heating instead of heating rods

- Insulated oil storage tank heated by a heat exchanger and oil filter system. The filtration takes place during production.

- Extraction hood

- Fire extinguisher (water-mist or foam)

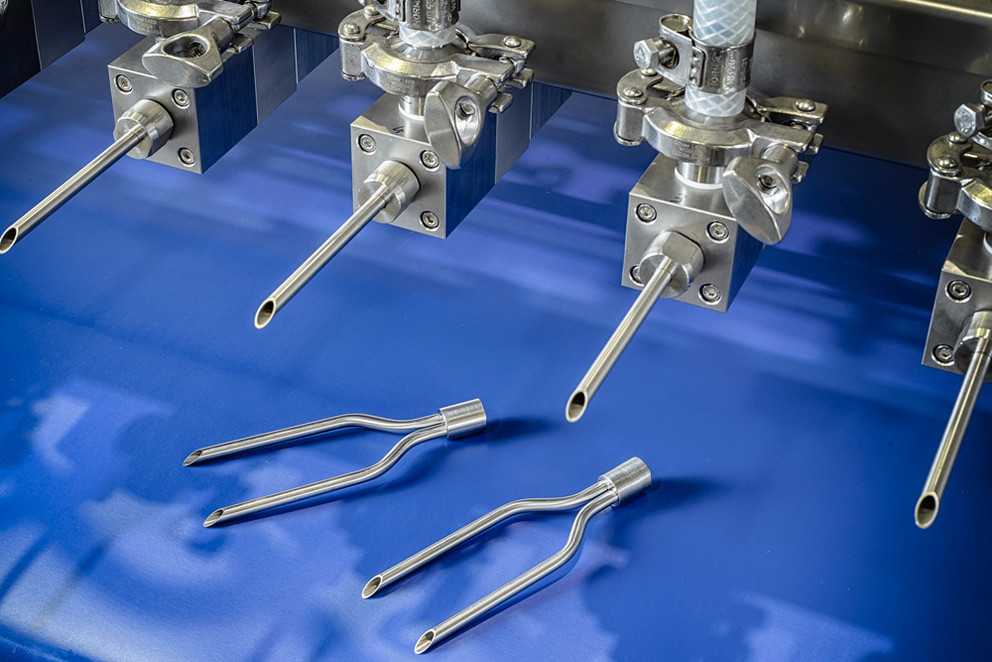

- Jam filling module for horiziontal or vertical filling. Filling needles single, multi-head or double

- Powder sugaring module on a mobile frame

- Depositing station as an attachment for curd balls, french crullers and cake donuts

Product variety

The LARGO fryer is available as an individual machine or as part of our turn-key solutions for the industrial ball donut production and/or donut production. Are you interested in the whole process? Then please visit one of our process solution or get in contact with us.

Donuts

Ball donuts

Curd balls

Long donuts

Apfelringe

Local specialities

French crullers

Cake Donuts

Service and support

We make sure that your production lines run.

Prevention

Our goal - reduce machine downtime and make them predictable through proactive maintenance.

Repairs

Faults can build up or just happen, no matter what precautions have been taken. When they do, it is vital to initiate and implement the necessary measures as soon as possible to let your lines run again.

Clean is important. Even cleaner is better. WP Clean Up

Extend the life of your machine with the machine cleaner WP CLEAN UP.