FutureWork

Investment in research and development improve our service and the production of our customers.

Service 4.0

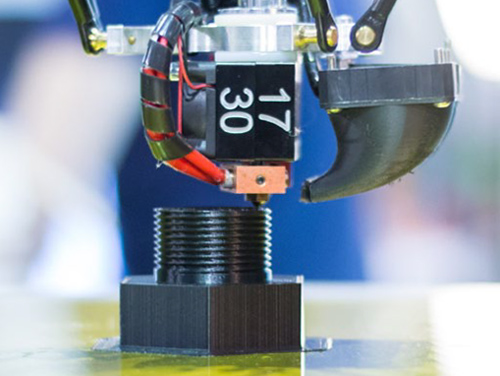

3D Printing: Individual solutions

Individually manufactured tools, such as stamping tools, make it possible to produce products with a Point of Difference.

Sensor-based productivity evaluation

Innovative sensor technology such as ViCONTROL for quality optimization and documentation and for productivity analysis.